Flow configuration example

This example demonstrates how to configure a flow that collects data from IoT devices, performs calculations to derive business-relevant metrics, and forwards the enriched data to an external system. The example uses a linear flow pattern that can be adapted to various industry use cases.

Business scenario

In this scenario, an organization has deployed IoT trackers on their assets and needs to process data from these devices for business analytics. The organization receives the following parameters directly from their tracking devices:

speed: Vehicle speed in kilometers per hourtemperature: Environmental temperature in Celsiusodometer: Distance traveled in kilometersignition: Engine ignition status (1 = on, 0 = off)fuel_level: Current fuel level measurementpressure_psi: Pressure reading in PSIvoltage: Battery voltage in voltsthrottle: Throttle pedal position from CAN bus (0-255)fuel_level_1: First fuel tank level measurementfuel_level_2: Second fuel tank level measurement

The organization needs to:

Collect raw telemetry data from devices to maintain a complete record of asset operations

Convert measurement units to match their standard reporting format (imperial units) for consistency with existing business systems

Calculate time-based metrics that indicate usage patterns to optimize asset utilization and maintenance schedules

Create derived metrics to generate operational insights not directly provided by the hardware

Forward the enriched data to an external analysis system for integration with business intelligence platforms

Send unchanged raw data to Navixy for monitoring

This flow will transform the raw device data into a format that directly supports business decision-making while maintaining the integrity of the original measurements.

Flow configuration steps

Follow these steps to build a comprehensive data transformation and forwarding flow:

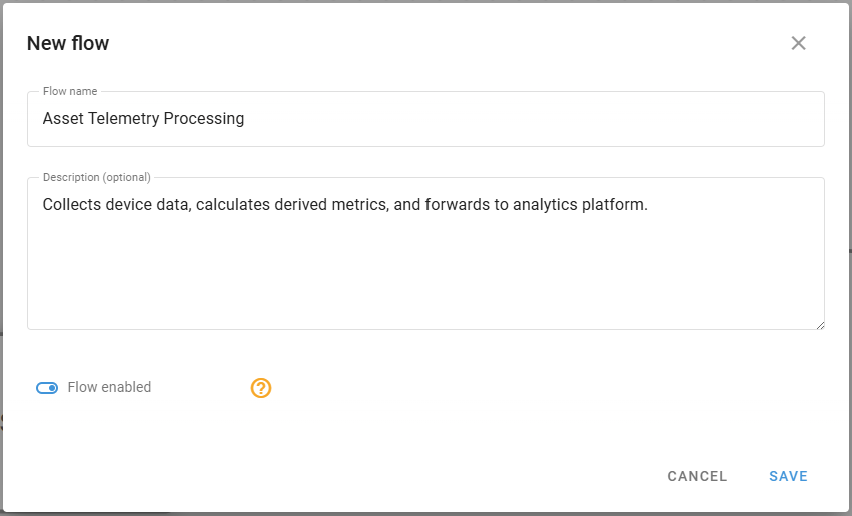

Step 1: Create a new flow

Click the New flow button at the top of the IoT Logic interface

Enter Asset Telemetry Processing as the flow name

Add a description: "Collects device data, calculates derived metrics, and forwards to analytics platform."

Ensure the Flow enabled toggle is switched on

Click Save to create the flow

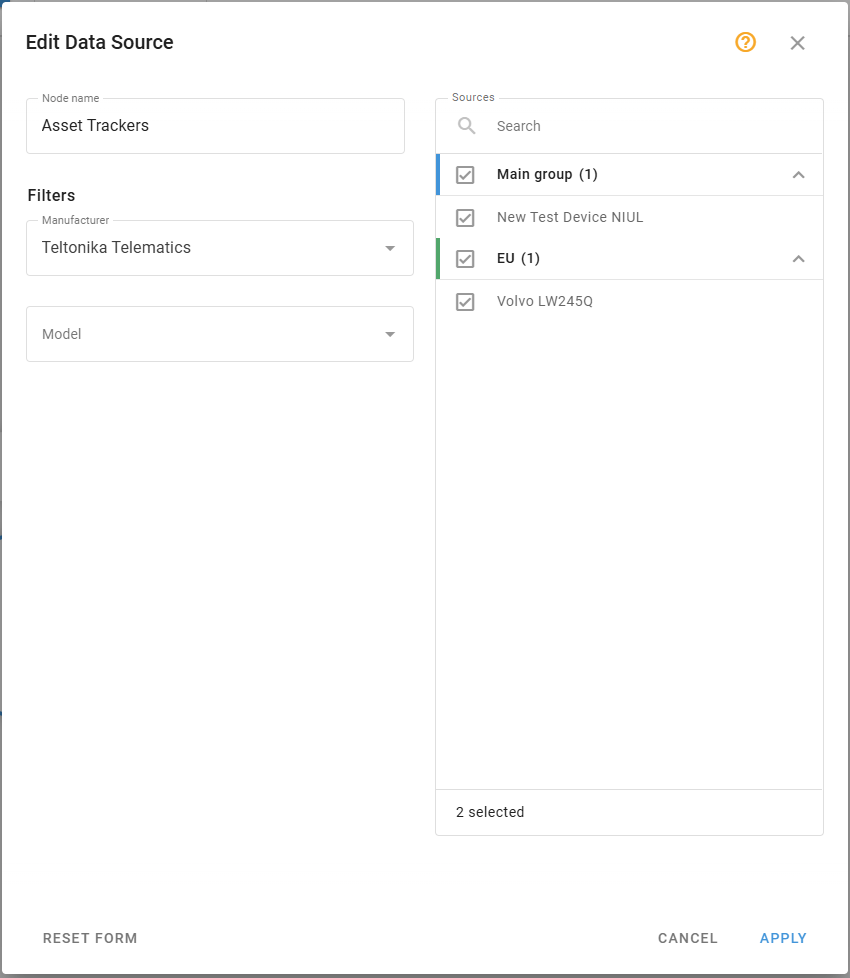

Step 2: Configure the data source

Drag a Data Source node from the left menu to the workspace

Double-click on the node to open its configuration panel

In Node name type Asset Trackers

Select the devices to include in this flow from the filtered list

For this example, select at least two devices with similar capabilities

Click Apply to save node configuration

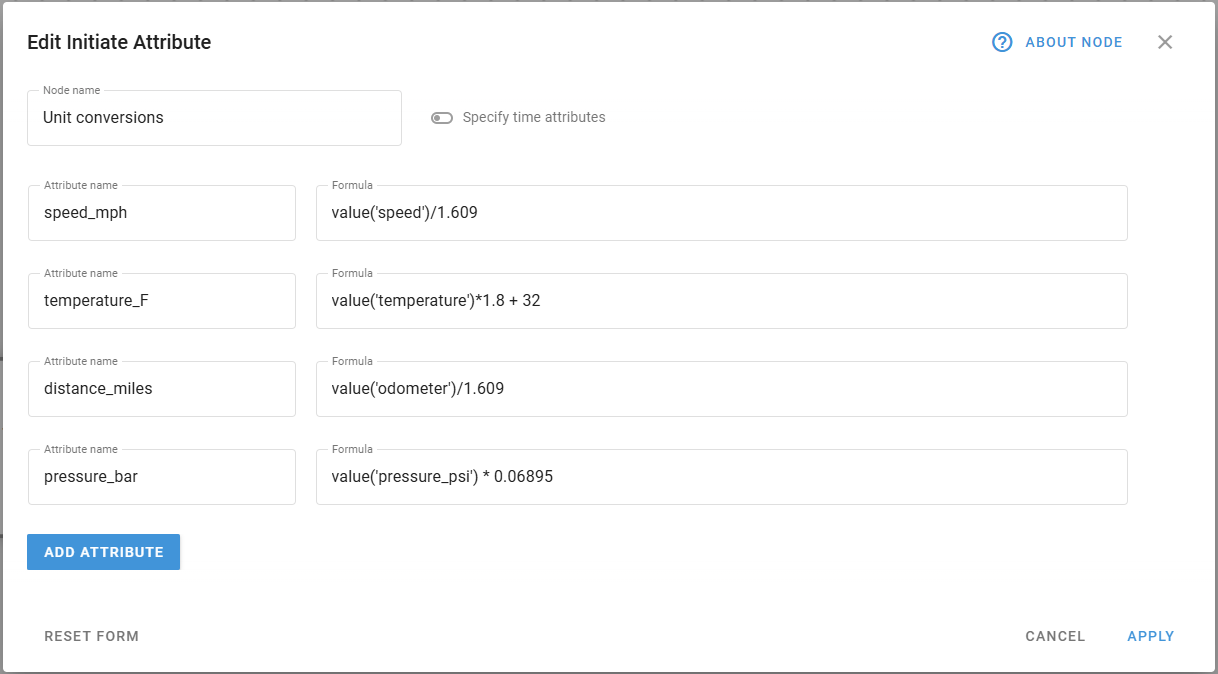

Step 3: Set up basic data transformations

Drag an Initiate Attribute node from the left menu to the workspace

Connect the Data Source node to this Initiate Attribute node

Double-click the node to open its configuration

In Node name type Unit conversions

Create the following attributes for unit conversion:

Add a new attribute for speed conversion (km/h to mph):

Attribute name: speed_mph

Value:

value('speed')/1.609

Add a new attribute for temperature conversion (Celsius to Fahrenheit):

Attribute name: temperature_F

Value:

value('temperature')*1.8 + 32

Add a new attribute for distance conversion (kilometers to miles):

Attribute name: distance_miles

Value:

value('odometer')/1.609

Add a new attribute for pressure conversion (PSI to Bar):

Attribute name: pressure_bar

Value:

value('pressure_psi') * 0.06895

Click Apply to save node configuration

For explanations on calculations introduced in this step, see Basic unit conversions.

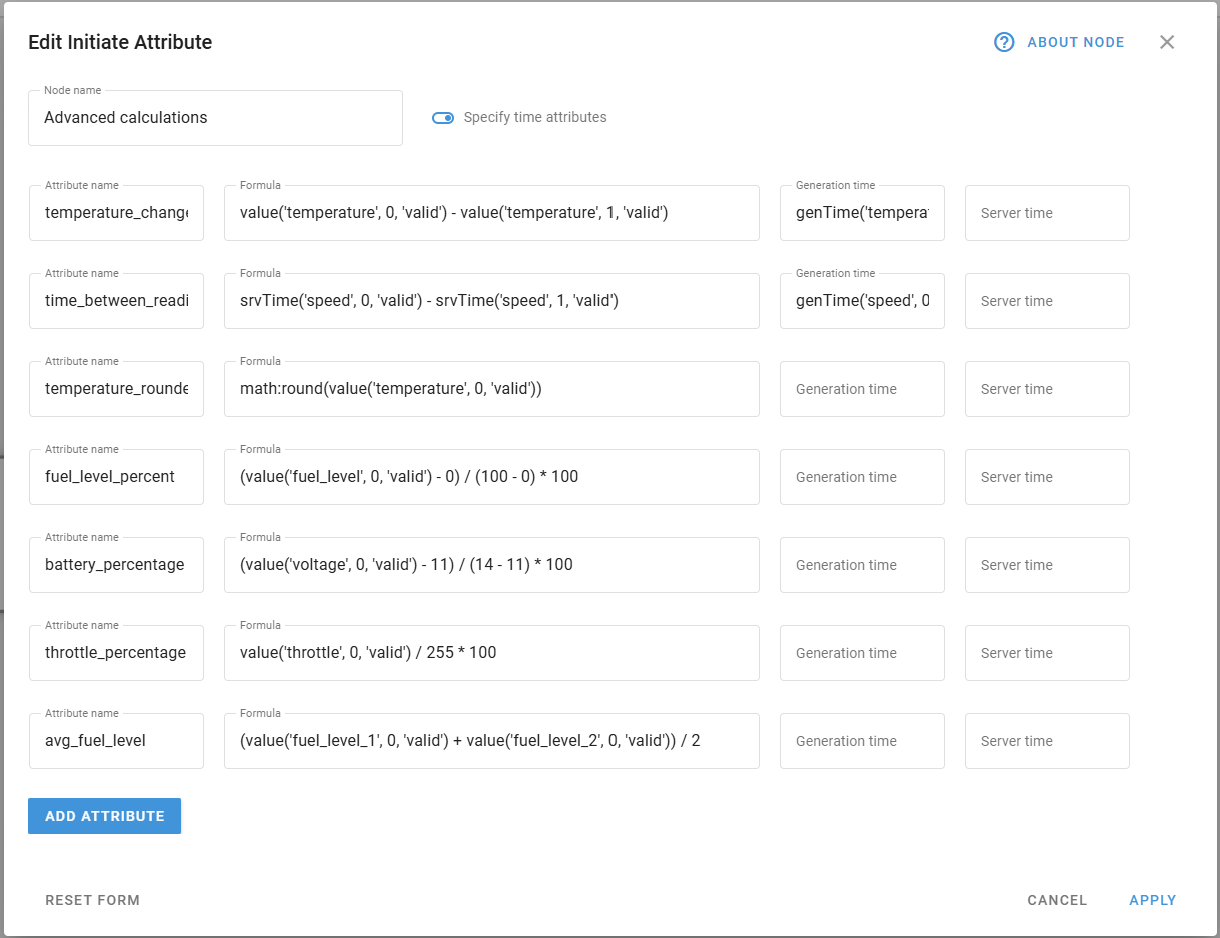

Step 4: Create advanced calculated metrics

Drag another Initiate Attribute node from the left menu to the workspace

Connect the first Initiate Attribute node to this new one

Double-click on the node to open its configuration

In Node name type Advanced calculations

Create the following attributes for advanced metrics:

Add an attribute for temperature change detection:

Attribute name: temperature_change

Value:

value('temperature', 0, 'valid') - value('temperature', 1, 'valid')Generation time:

genTime('temperature', 0, 'valid')

Add an attribute for finding time elapsed between two last readings:

Attribute name: time_between_readings_ms

Value:

srvTime('speed', 0, 'valid') - srvTime('speed', 1, 'valid')Generation time:

genTime('speed', 0, 'valid')

Add an attribute for round temperature to nearest integer:

Attribute name: temperature_rounded

Value:

math:round(value('temperature', 0, 'valid'))

Add an attribute for standardized value calculation (normalizing fuel level to 0-100%):

Attribute name: fuel_level_percent

Value:

(value('fuel_level', 0, 'valid') - 0) / (100 - 0) * 100

Add an attribute for battery charge percentage calculation:

Attribute name: battery_percentage

Value:

(value('voltage', 0, 'valid') - 11) / (14 - 11) * 100

Add an attribute for throttle position calculation:

Attribute name: throttle_percentage

Value:

value('throttle', 0, 'valid') / 255 * 100

Add an attribute for average fuel level from multiple sensors:

Attribute name: avg_fuel_level

Value:

(value('fuel_level_1', 0, 'valid') + value('fuel_level_2', 0, 'valid')) / 2

Click Apply to save node configuration

For explanations on calculations introduced in this step, see Advanced metrics calculations.

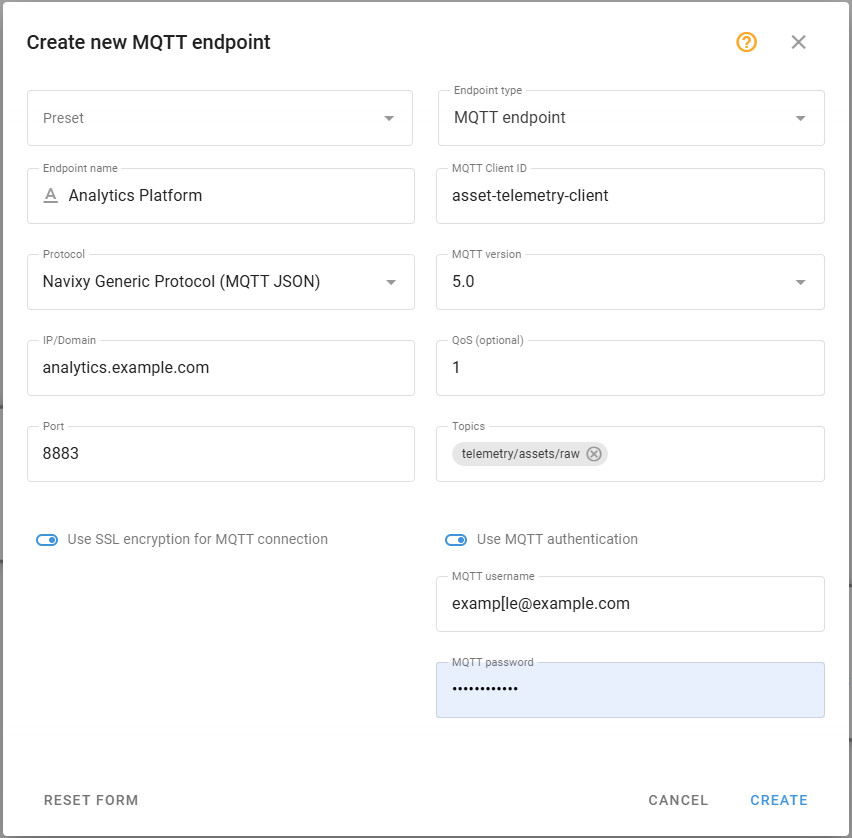

Step 5: Configure the output endpoint

Drag an Output Endpoint node from the left menu to the workspace

Connect the second Initiate Attribute node to this Output Endpoint node

Click on the node to open its configuration

Configure the following settings:

Endpoint type: MQTT endpoint

Endpoint name: Analytics Platform

Protocol: default Navixy Generic Protocol (JSON)

IP/Domain: Enter the destination system address (e.g., "analytics.example.com")

Port: 8883 (default for MQTT, you can leave it empty)

Enable SSL: toggle on

MQTT Version: 5.0

MQTT Client ID: asset-telemetry-client

Topic: telemetry/assets/raw

QoS: 1

MQTT Authentication: Yes (if required by your destination system)

MQTT Login and Password: Enter credentials if applicable

Click Create to save node configuration

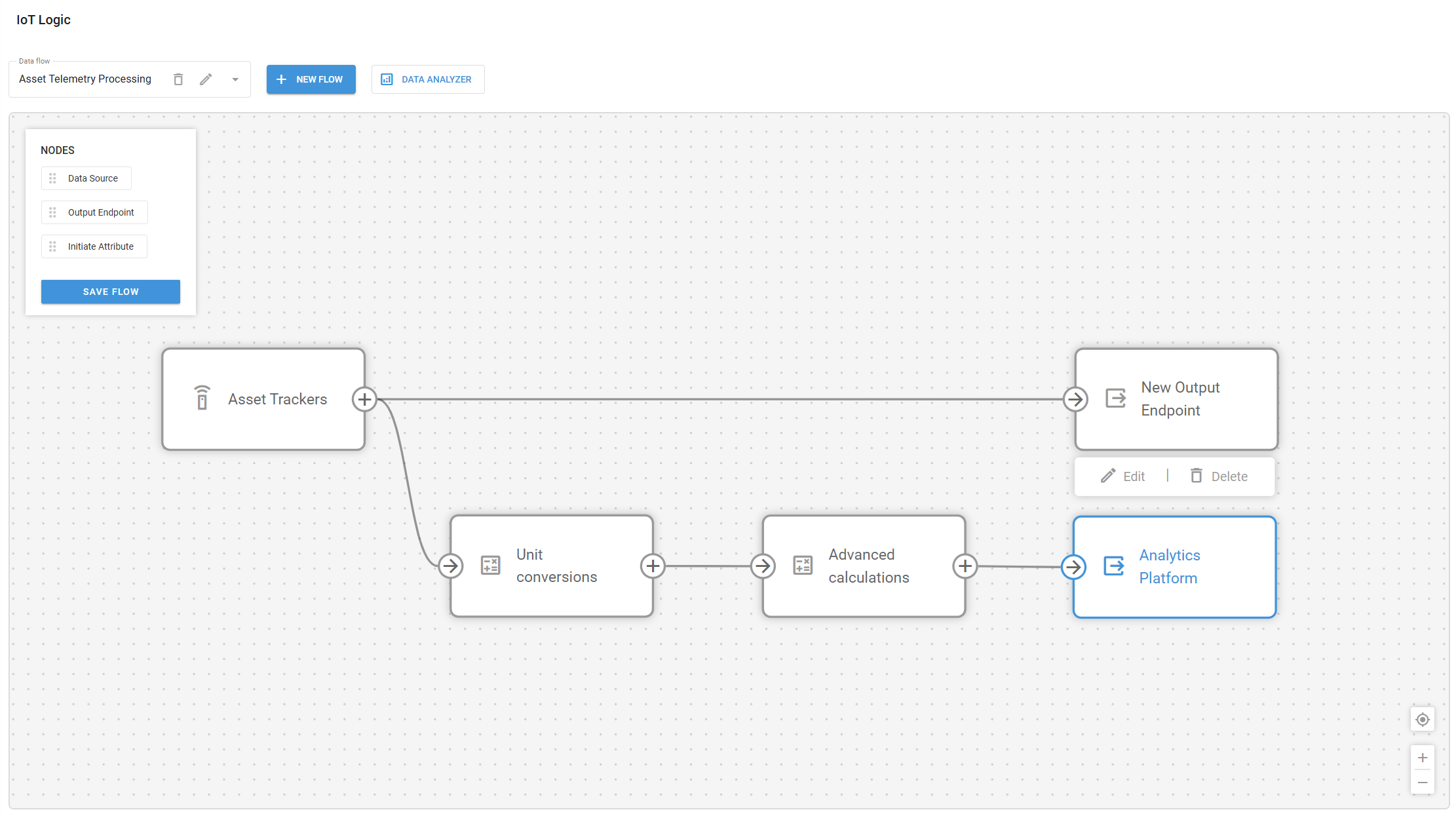

Step 6: Add Default endpoint

Drag an Output Endpoint node from the left menu to the workspace

In Endpoint type select Default Endpoint

Click Save to apply node configuration

Connect the Asset Trackers (Data Source) node to it

This ensures that the raw data is sent to Navixy directly from the devices, without any transformations and enrichments.

Step 7: Save and test the flow

Your final configuration will look like this:

Click the Save flow button on the Nodes pane to store your flow configuration

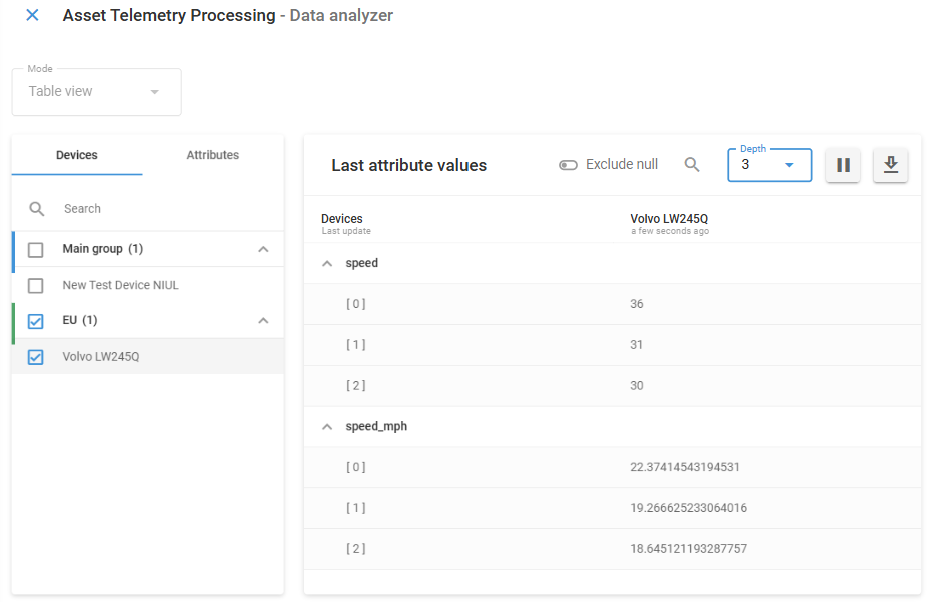

Use Data Stream Analyzer (DSA) to monitor incoming data to verify:

Devices are sending data to the flow

Calculations are working as expected

Data is being forwarded to the destination

For example, let’s check that speed conversions are calulated correctly on a truck. To do it in DSA, select the Volvo device and attributes speed and speed_mph:

All good! Data is received and converted successfully.

Data transformations explained

Let's examine the key calculations used in this flow.

Basic unit conversions

The first Initiate attribute node performs straightforward unit conversions:

Speed: Converts km/h to mph by dividing by 1.609

Temperature: Converts Celsius to Fahrenheit using the formula °F = °C × 1.8 + 32

Distance: Converts kilometers to miles by dividing by 1.609

Pressure: Converts PSI to Bar by multiplying by 0.06895, making it compatible with international pressure measurement standards

These conversions ensure consistency with standard reporting formats and make the data immediately usable for analysis. Unit conversions are particularly valuable for multinational organizations that operate across regions with different measurement standards.

Advanced metrics calculations

The second Initiate attribute node performs more complex calculations:

Temperature change detection: Calculates the difference between current and previous temperature readings to identify sudden changes. This helps detect equipment issues such as refrigeration failures in transport vehicles or HVAC problems in facilities. For example, a sudden 5°C rise in a refrigerated container might indicate a cooling system failure requiring immediate attention.

Generation time: Using

genTime('temperature', 0, 'valid')is crucial here because it preserves the exact timestamp when the temperature reading was generated by the device, ensuring accurate time-based analysis of temperature changes.Server time: The default value

now()automatically captures when the server received the data. Since we don't need to modify this timestamp, we can leave this field empty during configuration.

Time between readings: Measures the interval between consecutive data transmissions by comparing server timestamps. This calculation helps identify communication issues or validate that devices are reporting at expected frequencies. Irregular intervals might indicate connectivity problems, while consistent delays could suggest network congestion or device configuration issues.

Rounding values: Applies mathematical rounding to temperature readings, reducing decimal precision to integers. This simplifies data visualization and reporting while reducing storage requirements for historical data. Rounded values are especially useful for dashboard displays and threshold-based alerts where decimal precision isn't necessary.

Generation time: Specifying

genTime('speed', 0, 'valid')connects this metadata directly to the original reading's timestamp, making it possible to analyze both the time interval and when it occurred.Server time: The default value

now()automatically captures when the server received the data. Since we don't need to modify this timestamp, we can leave this field empty during configuration.

Standardized value calculation: Normalizes raw sensor readings to a percentage scale (0-100%). This standardization makes it easier to compare readings across different sensor types and vehicle models. For fleet management, this allows consistent fuel level reporting regardless of the specific fuel sensor implementation in each vehicle model, enabling uniform low-fuel alerts and consumption analysis.

Battery charge percentage calculation: Normalizes battery voltage readings (11V-14V range) to a 0-100% scale for easier monitoring. For example, a reading of 12.5V would be normalized to 50%, providing an intuitive indicator of battery health across different vehicle types.

Throttle position calculation: Converts raw throttle position data (0-255 range) from the vehicle's CAN bus to a percentage scale. This standardization helps operators quickly understand driver behavior and vehicle performance without needing to interpret raw sensor values.

Average fuel level from multiple sensors: Combines readings from two separate fuel sensors to produce a more accurate overall fuel level measurement. This is particularly valuable for vehicles with complex tank shapes or multiple tanks, where a single sensor might not provide reliable readings due to fuel shifting during movement.

Example flow summary

This flow configuration demonstrates several key IoT Logic capabilities:

Standardization: Converts device-specific readings into standardized business metrics

Enrichment: Creates new, meaningful metrics not directly available from device sensors

Transformation: Changes units to match business reporting requirements

Historical context: Uses previous readings to calculate trend-based metrics

Status determination: Creates categorical values based on multiple sensor inputs

This combination of capabilities transforms raw device data into actionable business intelligence, directly supporting operational decision-making while maintaining the integrity of the original measurements.